How to Size and Tune Fuel Injectors

Choosing the right fuel injectors is one of the most important steps in any engine build. If you’re tuning or taking your car to get tuned, incorrect injector sizing can create a chain of issues that affect drivability, power delivery, and engine longevity.

If you’re injectors aren’t so healthy, they’re running out of puff, or you’re making hardware changes, you should be considering cleaning, replacing or upgrading your injectors.

I’ll share my knowledge from years of injector cleaning, testing and putting together tuning packages, so the engine tuner gets owners like you the best results: maximum reliability and drivability. That means understanding how injectors work, the types available, and how to choose the most suitable injector.

What Fuel Injectors Actually Do?

Fuel injectors are electronically controlled valves that spray fuel into the intake port or combustion chamber in fine, atomised form. The ECU tells each injector when to open and for how long. The amount of time an injector stays open is called pulse width.

A longer pulse delivers more fuel, while a shorter one delivers less. At high RPM or boost, the ECU widens the pulse width to keep up with airflow.

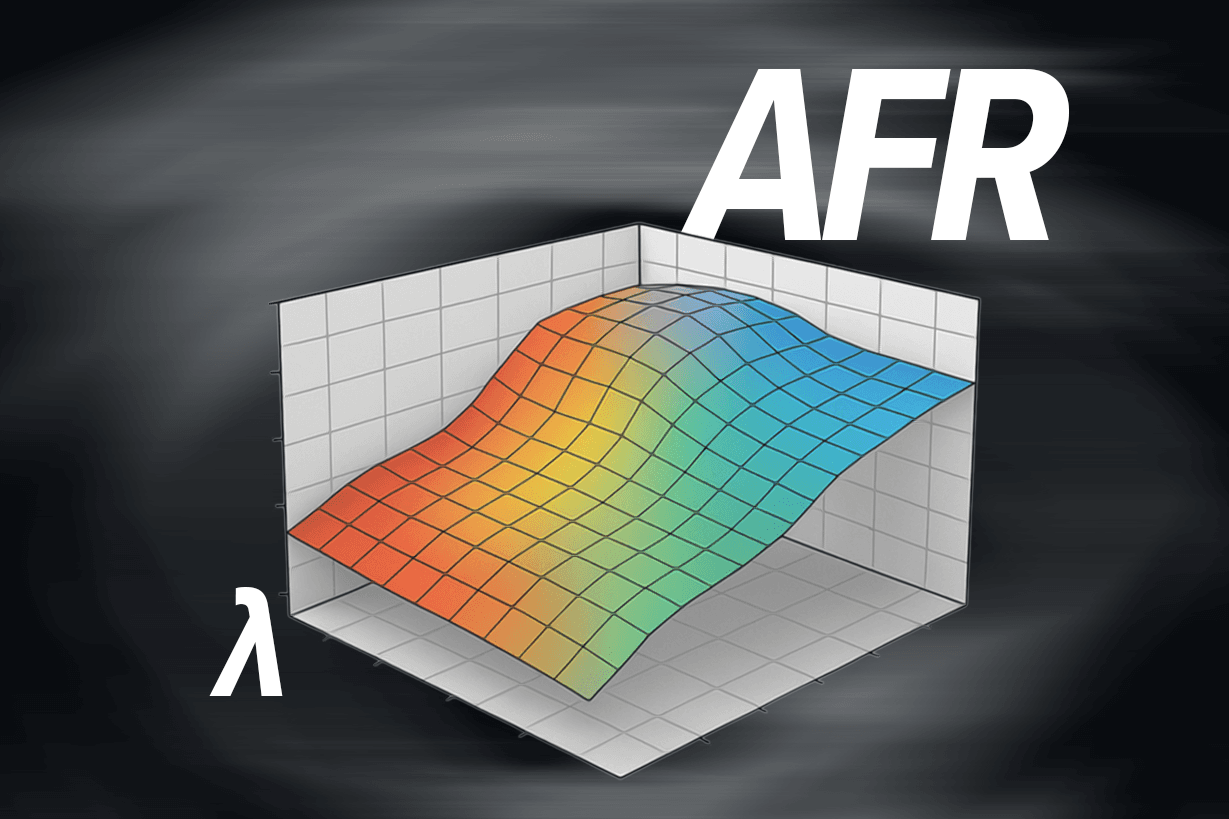

It is very important that the injector supplies enough fuel to match the air entering the engine while keeping the air/fuel ratio in the correct range.

Types of Injectors: High vs Low Impedance

Injectors are categorised by their electrical resistance:

High Impedance (Saturated):

- Typically 12–16 ohms

- Used in most modern vehicles

- Compatible with factory and aftermarket ECUs

- Ideal for street and performance builds

Low Impedance (Peak-and-Hold):

- Typically 2–4 ohms

- Require special driver circuits

- Found in older or race-only setups

Unless you’re using a standalone ECU that supports low-impedance injectors, high-impedance is the safer and more flexible choice.

Are Injectors Universal?

Not exactly. Injectors differ in:

- Physical size (length and diameter)

- Electrical connector (EV1, EV6, USCAR, etc.)

- Impedance (high vs low)

- Flow rate (measured at a given pressure)

Always check compatibility with your fuel rail, wiring harness, and ECU before buying.

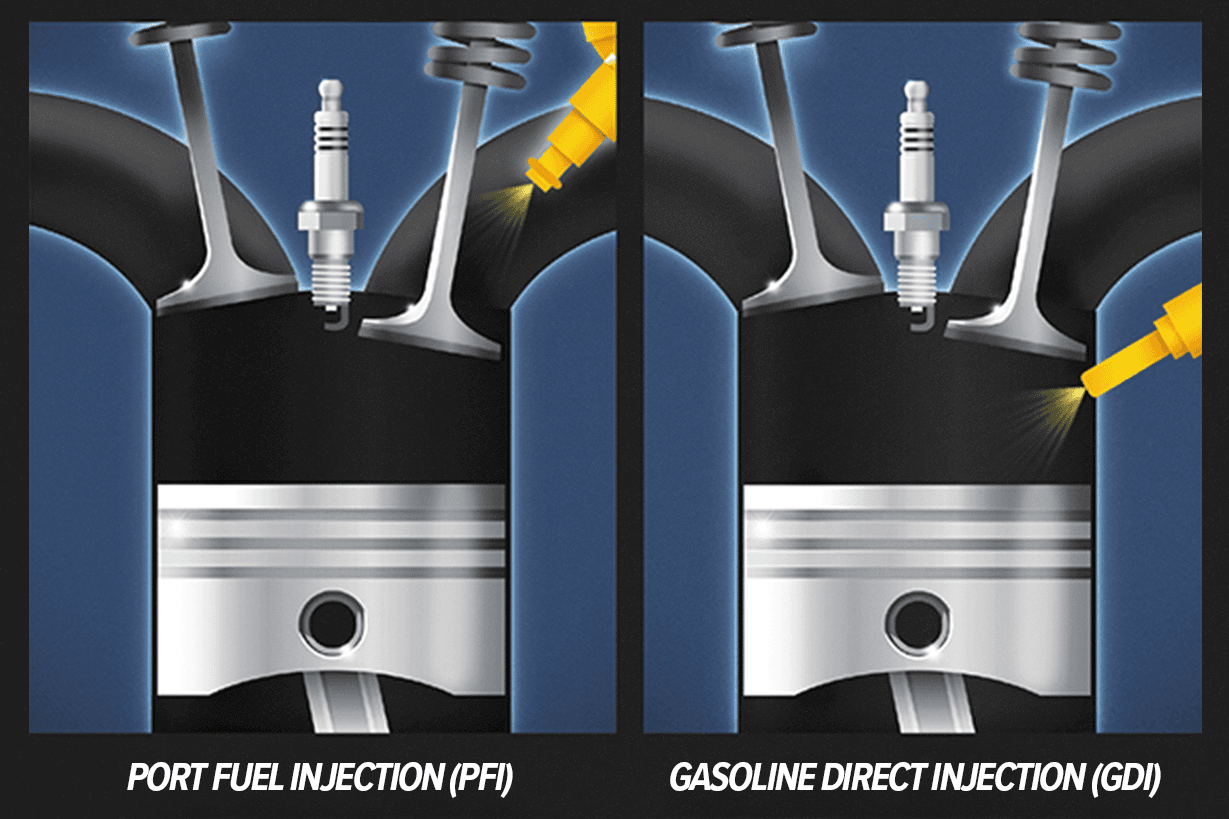

Port vs Direct Injection (and Both)

Most modern engines use port injection, direct injection, or both. Each has its benefits and drawbacks.

Port Fuel Injection (PFI):

- Sprays fuel into the intake port, cleaning valves as it passes.

- Easier to tune and upgrade.

Gasoline Direct Injection (GDI):

- Sprays fuel directly into the combustion chamber.

- Higher efficiency and power potential.

- Prone to carbon buildup on intake valves (especially in turbocharged engines).

Dual Injection (PI + DI):

- Helps reduce valve carbon buildup.

- Improves low-load drivability and fuel economy.

- Not all ECUs support it.

Back when I worked at JBM Performance, we frequently performed walnut blasting on DI-only engines with heavy carbon deposits. Dual systems are an ideal compromise when available, especially if you’re increasing power.

Spray Patterns: Do They Matter?

Absolutely. Different injectors have different spray patterns and cone angles, designed for:

- Intake port geometry

- Piston crown shape

- Number of valves per cylinder

- Fuel type (petrol, ethanol, methanol)

Choosing the right spray pattern helps ensure:

- Complete combustion

- Reduced emissions

- Even fuel distribution

Your intake manifold, combustion chamber shape and power goals should guide spray pattern selection. Mismatched spray can lead to puddling, uneven AFR, or poor atomisation.

Sizing Injectors Based on Horsepower

Once you’ve chosen the type and physical style, it’s time to size the injectors correctly.

Use this formula:

Required Injector Size (lbs/hr) = (Target HP × BSFC) / (Number of Injectors × Duty Cycle)

Where:

- BSFC is Brake Specific Fuel Consumption (in lbs/hp/hr)

- Petrol NA: 0.45–0.50

- Petrol Boosted: 0.60–0.65

- E85 NA: 0.65–0.70

- Duty Cycle should be kept below 85%, ideally around 75–80%

Example:

A 500 hp naturally aspirated V8 on petrol:

(500 × 0.50) / (8 × 0.80) = 31.25 lbs/hr per injector

Round up to the nearest available size. In this case, a 36 or 42 lbs/hr injector gives a safer margin.

Why You Shouldn’t Just Buy the Biggest Injectors

It’s tempting to go big “just in case,” but massive injectors come with downsides. Injectors are most accurate in their midrange. When oversized, they struggle to deliver very short pulses cleanly, especially at idle.

Problems you may face:

- Rich or unstable idle

- Poor throttle response at low loads

- Difficulty maintaining a stable AFR

- ECU struggles to trim fuelling properly

Larger injectors also require more precise ECU tuning. That may not be possible with a piggyback or factory ECU.

Oversize modestly, just enough to keep the duty cycle below your target. If your build makes 480 hp and you’re buying injectors for 1000 hp “just in case,” expect drivability issues unless your ECU and tuner are up to the task.

Why Duty Cycle Matters

Duty cycle is how long the injector stays open per engine cycle, expressed as a percentage.

- 100% = Wide open all the time (unreliable)

- 85% = Safe upper limit

- 70% = Ideal for headroom and longevity

Injectors become less predictable near 100%. Staying in the midrange ensures better atomisation, accurate control, and easier tuning.

Can Injectors Cause a Misfire?

Yes. If an injector is clogged, too small, or running out of flow at high RPM, you’ll see misfires under load. This is especially common in turbo cars, where the airflow spike overwhelms the injector capacity.

A misfire from fuelling will often show up only at high throttle or boost.

Clean, Replace or Upgrade?

Knowing whether to clean, replace or upgrade your fuel injectors depends on symptoms, mileage, performance goals, and what stage of your build you’re at. Below are some guidelines to help you decide what action is most appropriate.

When to Clean Fuel Injectors

Cleaning is best when your current injectors are still suitable for the build but showing signs of wear or inconsistent fuelling.

Clean your injectors if:

- AFR is unstable despite good ECU calibration

- You suspect clogging, varnish or dirty spray patterns

- You’re reusing injectors from a previous build or long storage

- Misfires or hesitation appear under light load or idle

- Fuel economy has suddenly dropped

Ultrasonic cleaning can restore the spray pattern and flow accuracy. Always use a reputable injector cleaning service that can flow test before and after. Basic “in-tank” fuel additives are rarely effective for real deposits.

When to Replace Injectors

Sometimes cleaning isn’t enough, or injectors are simply past their prime. Replace them if:

- One or more injectors fail a flow test or leak

- You’re using old high-mileage injectors, and performance is erratic

- Spray pattern is visibly poor or uneven

- You’re still on OEM injectors and making minor power upgrades

- The injectors are physically damaged or cracked

If you’re not drastically changing power levels, replacing your injectors with OEM or OEM+ rated ones is a safe and reliable option.

When to Upgrade Injectors

Upgrading injectors is necessary when the current ones can’t meet your engine’s fuelling demands, or you’re moving to a fuel that requires higher flow.

Upgrade if:

- Duty cycle is hitting or exceeding 85% at WOT

- You’re switching to ethanol (E85 or similar), methanol, or race fuel

- AFR leans out at high RPM or boost despite healthy injectors

- You’re adding a turbo, supercharger, camshafts or significantly raising power

- Your ECU tuning reveals limitations at high load

Keep future plans in mind. Upgrading to slightly larger injectors now can save you from buying another set down the line.

Understanding BSFC

Brake Specific Fuel Consumption tells you how much fuel (in pounds) is used to produce 1 horsepower for 1 hour.

| Fuel Type | NA Engine BSFC | Boosted Engine BSFC |

|---|---|---|

| Petrol | 0.45–0.50 | 0.60–0.65 |

| E85 | 0.65–0.70 | 0.85–0.90 |

| Methanol | 0.90–1.00 | 1.80–2.00 |

The higher the BSFC, the more fuel is needed. Switching to E85 or methanol requires larger injectors.

How Fuel Pressure Changes Flow

Injectors are rated at a standard pressure of 3 bar (43.5 psi). Higher pressure = more flow. Lower pressure = less flow.

To calculate the new flow rate:

New Flow = Rated Flow × √(New Pressure / Rated Pressure)

Example:

An injector rated at 42 lb/hr @ 43.5 psi:

42 × √(58 / 43.5) = ~48.7 lb/hr

Raising pressure is a short-term fix. If you’re increasing power, step up the injector size instead.

Are Injectors Easy to Replace or Upgrade?

If you’re replacing injectors with identical new units or a flow-matched set with the same specs, the process is relatively simple.

Replacing Injectors (Same Specs)

Mechanically – Yes:

- Depressurise the fuel system

- Remove the fuel rail and old injectors

- Lubricate and fit new O-rings

- Install the new injectors and refit the rail

Electronically – Not Always Needed:

- If flow rate, latency, and injector data are identical, ECU adjustments may not be required

- It’s still good practice to verify fuel trims and AFR, just in case

Note: Even with same-spec replacements, always verify there are no leaks, misfires, or injector performance discrepancies after installation.

Upgrading Injectors (Different Specs)

If the injectors have a different flow rate or characteristics, engine tuning is essential.

ECU must be recalibrated:

- Injector scaling

- Dead times/latency

- Base fuel and correction maps

- Cold start enrichments (especially on factory ECUs)

Without tuning, the engine may run too rich or lean, with poor idle quality and unpredictable AFR.

Installing Injectors Before Tuning: Risks and Precautions

In a perfect world, injectors should be installed at the time of tuning. However, many owners want to save on labour by installing the new injectors themselves beforehand.

At JBM Performance, we had customers drive their vehicles to the dyno after fitting injectors at home. If you choose this route, take precautions:

- Install matching O-rings and check for leaks

- Keep your foot light. Don’t stress the fuel system

- Avoid boost or full throttle

- Use a conservative base fuel map if possible

- Check fuel trims and monitor AFR closely

It’s not ideal, but it can be done safely if you’re careful and understand the risks. A proper tune should follow immediately.

Final Thoughts

Fuel injectors are critical. Once you understand how they work and how to size them correctly, you can build power safely. The right injectors must be fitted, but it’s even more important that they are correctly configured in the ECU. Avoid fitting injectors that you don’t know the specifications for. Use part numbers to cross-reference spec sheets if you need to, but don’t guess.

To summarise:

- Choose the right type and impedance

- Calculate flow rate based on HP and BSFC

- Leave duty cycle headroom

- Tune after installation

Getting this right means smoother drivability, safer tuning, and more room to grow your setup. From here, you should be on track for reliable power.

If you have any doubts, speak to your tuner. They will be the ones trying to extract results from whatever setup you bring them.